volvo ex90

- team work

client: Volvo Cars

duration: 2 years

delivery: 2021

brief: participate in the design development & industrialization of the EX90 until its production-ready status thanks to an engaged collaboration with many other professions.

learnings

Among the various projects I’ve worked on, the Volvo EX90 stands out as my most significant contribution to the current Volvo lineup. Over two years of intense production work, I gained a deep understanding of the industry's heritage, its challenges, and areas for improvement.

Most importantly, I discovered and learned what it means to be an interior designer at an automotive company. As a matter of fact, it is very different from what we learn at school, which I could argue is something that could improve. Hopefully, reading this project page will give you an idea of what that role entitles.

the production world

When I started working in January 2020, I joined the EX90 project, which was already on-going. The project was at what we call a DSM3 stage in the automotive industry. This meant the overall design theme had been selected and my task was to refine the design in a way that it is both industrialization-ready and as close as possible to the intended design. It was my first real experience of the production world.

Working on the Volvo EX90 taught me that interior design is as much about collaboration as creativity. Thanks to talented designers and managers like Matthew Hunt and Niklas Palm, I learned the importance of uniting people around shared goals and fostering a true sense of teamwork across the whole process. I’m grateful to have grown through the diverse perspectives around me and to have worked with such incredible people on such an inspiring product.

“As an interior designer working on “hardcore production work”, I learned the importance of uniting people around shared goals and fostering a true sense of teamwork across the whole process.”

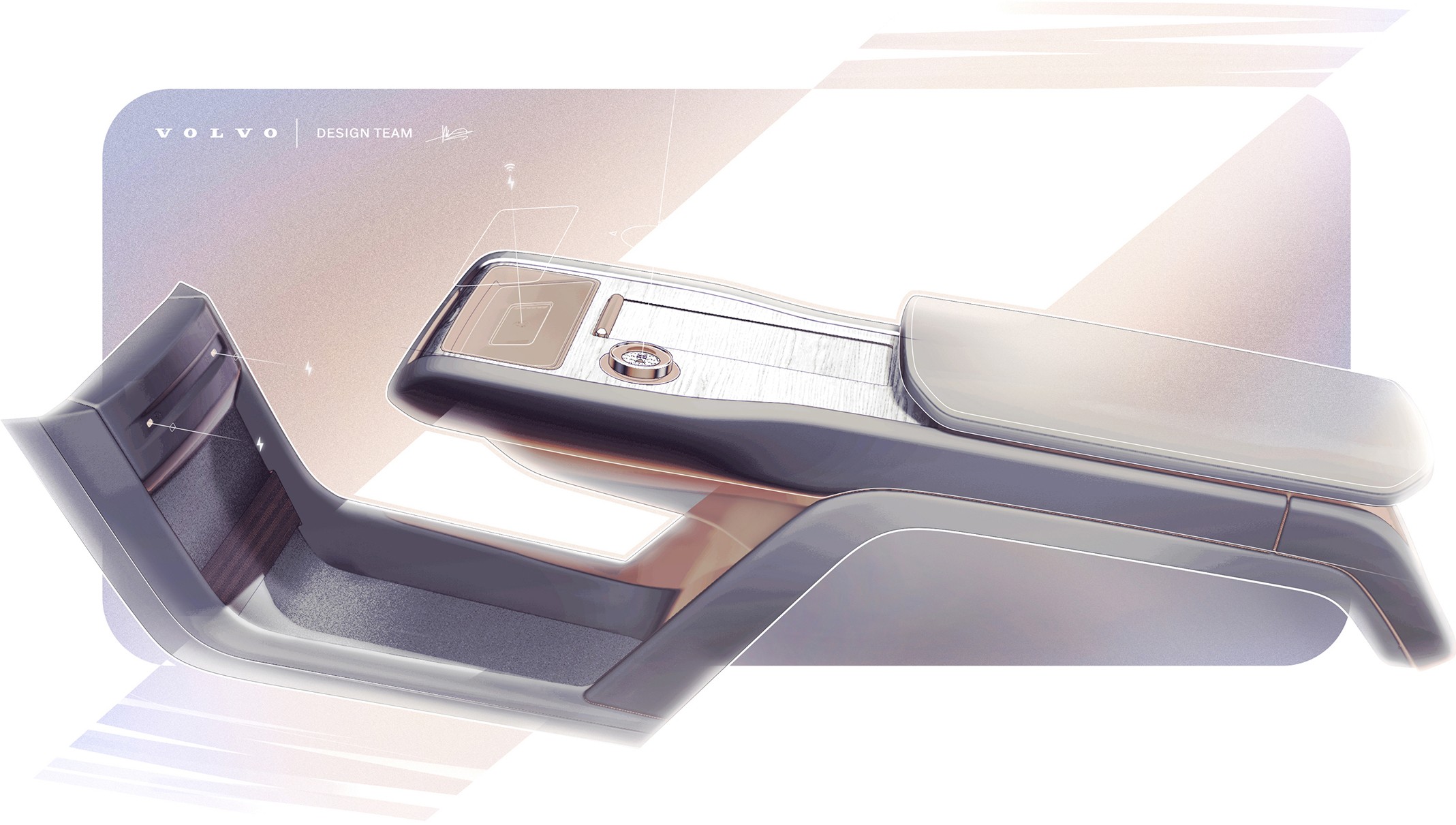

user focused center console

Developing the center console was first assignment within the EX90 project. The main design aspect of this part of the interior was this feeling of openess. One of the benefit of an EV is that the powertrain frees up a lot of space in the interior. As a result, there is more space available to bring smart design features to the users.

STUDIO ENGINEER / SURFACE MODELLER / INTERIOR DESIGNER

Designing a car is true teamwork. As an interior designer, my core partners were a studio engineer and a surface modeler. Maria Järdhult, our studio engineer, helped create a shared language and workflow between engineering and design. Arnaud Page, our surface modeler, translated ideas into precise 3D surfaces that met all production requirements.

Together, the three of us were responsible for creatively solving the challenges that came our way.

Together we pushed through concepts such as this elastic band at the front of the lower console, which allows users to safely store their phone and charging cables. I also learned how to use clay as a development tool and understood the importance of real-life testing and prototyping.

“Designing a car is true teamwork. As an interior designer, my core partners were a studio engineer and a surface modeler. Together, the three of us were responsible for creatively solving the challenges that came our way.”

At Volvo Cars, all visible parts are designed. Some were designed before-hand, in previous projects and are “carried over” to newer models as a smart way to save costs. Most of the top of the center console was carried over from the Polestar 3, which had already been designed by then. But the charging pad and the jalousie handle required change to make them more user-friendly.

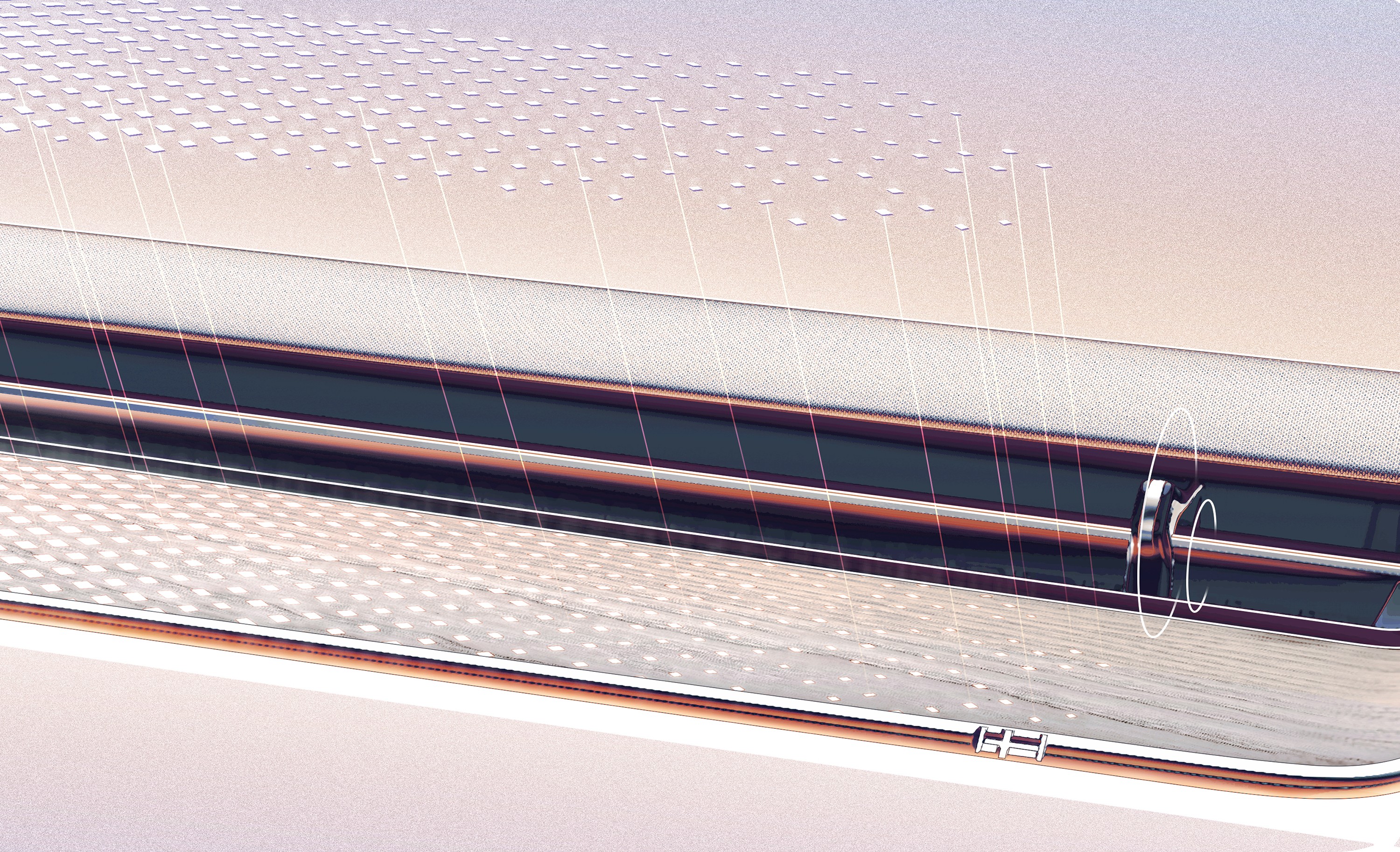

sophie tillema’s press sketch

I’m really proud we've achieved a good design that keeps the user in mind. This press sketch from Sophie Tillema illustrates perfectly the intention. We made sure that the storage space was large enough for a handbag to be placed in the lower front area, that the USB ports were visible and accessible to both front passengers, and that the rear area of the console was visually clean, emphasising the legroom for rear passengers and a good set-up for charging electronic items.

The aim was to create an experience as clean as possible, while still providing enough functionality.

check out Sophie’s press sketches!

Ev’s have frunks

The development of the EX90's frunk was also a big part of my assignment. Although here I started from scratch and followed the production process through to the final production-ready design.

For context, a “frunk” is a front trunk. It’s another consequence of the EV powertrain, where the actual engine is significantly smaller compared to a standard combustion engine. For the users, the benefit is clear as it frees up space that can be used for storage purposes.

Together with Vagner Amann, the studio engineer, we explored various alternatives for storage in Blender 3D to understand the available volume and how to best shape it according to the technical elements underneath. Then, together with Adam Björkqvist the surface modeler, we developed the first drafts of surfaces and refined them continuously.

a frunk as a premium tool-box.

The frunk was part of the car’s premium experience: an organized emergency toolbox for safety items, with room left for personal storage.

The cherry on top of the cake? A patented washer fluid opening! I would be surprised to hear that you never spilled any fluid out of the dedicated funnel, especially during winter, when it’s dark and cold. Well, Niklas Palm really wanted us to find a solution for it. So we did! We created an opening wide enough so that pouring the fluid gets spill-proof!

“Equally important was learning to truly collaborate, with everyone I encountered. To me, working together means creating a shared sense of purpose, where each person feels part of the same team.”

3rd row armrest

My last contribution to the EX90 was in the luggage area where I developed the 3rd row armrest for the 7 seater version of the EX90. It was a great challenge for me and John Lindhal, the studio engineer for the luggage area, as it had to be easy to produce but still provide a user friendly experience.

Between all the requirements and restrictions for cup size, seat folding and general packaging challenges, we managed to find sufficient space for a small storage unit, with USB charging. Its design is inspired by the doors while adapted to the use of plastic in this area.

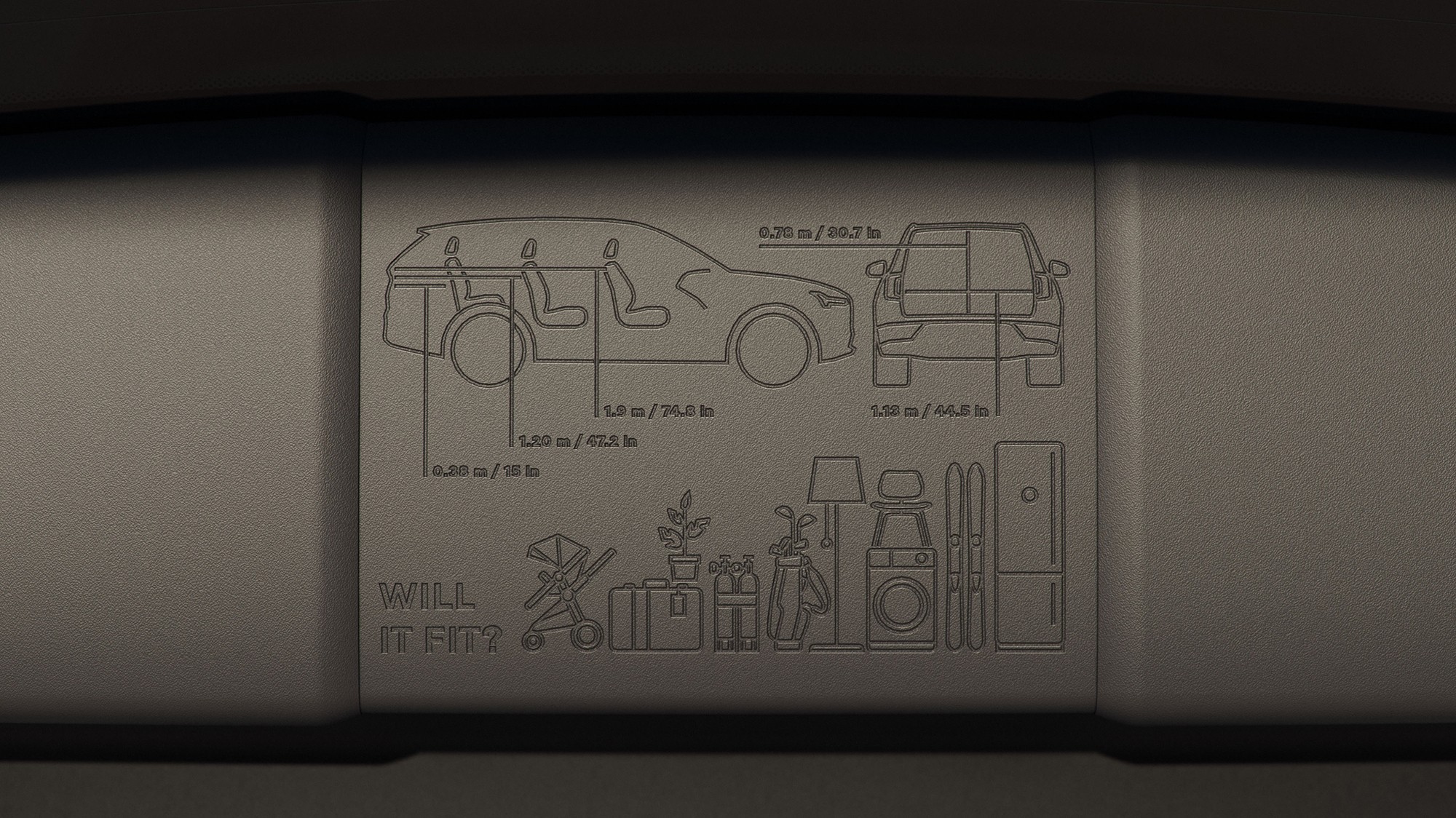

Finally, I had the chance to collaborate with some graphic designers to create this "Will it fit?" graphic. The idea was simple: instead of emphasising the size of the trunk, we decided to give the user more useful information by writing measurements on the inside of the tailgate.

A look back at this experience

My experience as an interior designer at Volvo Cars taught me to balance creativity with the many factors that shape a vehicle’s interior: ergonomics, feasibility, regulations, cost, and the countless details that give a design its meaning. This thirst for understanding has always guided my work.

I also learned the importance of asking the right questions. Continuously challenging the “why” or “why not” helped keep our intentions clear and our outcomes strong. I’m grateful to the colleagues and managers who trusted me, and this experience strengthened my ability to challenge both others and myself in a constructive, thoughtful way.

Matthew

Hunt

senior interior designer, Volvo Cars

“Throughout our collaboration on the Volvo EX90 interior, Thibaud was an invaluable part of the design team. He brought clarity of thought, creativity, and a huge amount of energy to the program.

His input shaped key elements of the interior experience, and his attention to detail pushed both himself and the rest of the team towards achieving a result we could all be truly proud of.”

related projects

check all projects